FIRE SURVIVAL CABLE

FIRE SURVIVAL CABLE

These cables offer the advantages of an armored 600/1000V rated, zero halogens, low smoke cable with circuit integrity. Ensuring the safe operation of critical circuits is essential in today’s installations. Standard cables used in such installations render useless in fire incidences. At Tescab Cables, your safety is our concern. These cables – also known as CIRCUIT INTEGRITY CABLES are designed to sustain high temperatures for a defined minimum period of time under direct fire. These cables are useful to maintain their integrity during the defined period of fire. The construction of these cables is different if compared with ordinary cables. The conductor is manufactured with a specially designed heat barrier and fire-resistant insulation which resists the fire from reaching the conductor surface. The cable continues to remain in operation at high temperatures like 650°C, 750°C, and 950°C as per various conditions of operation and applications. Wires offering the same properties are also available.

Specification

These cables are manufactured and tested in accordance with BS 7846, IS 7098(P-1), IEC 69331 and BS 6387 for required temperatures and duration – depending upon the application of cable and site conditions.

Constituents

Tescab cables fs cables are manufactured with the following materials.

- Annealed Plain Copper Conductor

- Heat Barrier Over the Conductor

- Cross-Linked Polyethylene

- Galvanised Steel Armour

- Zero Halogen & Low Smoke Compound

The ZHLS compound ascertains the minor smoke and hence increased light transmission during the burning of cables. The circuit integrity of FS cables at high temperatures remains unaltered for the required time period as per the specification defined.

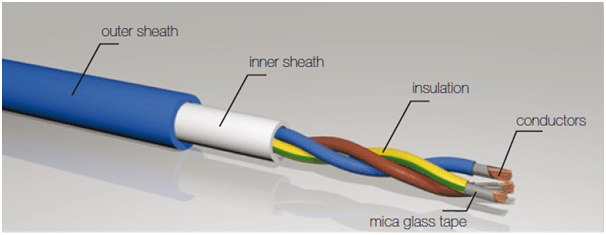

Construction

Conductor

Stranded annealed copper wires as per BSEN : 60228, IS 8130, IEC 60228

Fire Retardant Insulating Barrier

Glass Mica tape/ tapes applied helically

Insulation

Low Halogen Thermosetting XLPE

Laying Up Of Cores

Laid up and lapped with binder having HCL level less than 0.5 % by weight.

Inner Sheath

Galvanized steel round wire armoured with heavy duty zinc coating

Outer Sheath

Extruded layer of Halogen Free Low Smoke polymeric material.

Inner Sheath

Extruded layer of Halogen Free low smoke polymeric material